5 Piece ConstructionPreferred by architects and buildersManufactured by: Standard Supply, Inc. 6001 Zero Street Fort Smith, AR 72903 T 479-783-6755 1-800-380-3673 F 479-783-8920 standardfireboxes@gmail.com |

A fireplace has become an essential luxury in the architectural design of today's most gracious homes. More than ever before, contemporary home builders are focusing the mood of the central living area around the fireplace, making it the axis of the designer's concept in every conceivable style.

Versatile masonry products have standardly been incorporated in fireplace construction to fulfill the basic requirements of an efficient construction (combustion, heat radiation, smoke delivery, safety, and simplicity), and although many methods of firebox construction have been employed in achieving this goal, never before has any product nearly approached the effectiveness of the Standard Refractory Firebox.

Engineering

Standard Precast fireboxes are made of a castable, refractory concrete which is extremely resistant to corrosion, thermal shock, spalling, and soot or impingement build-up. Designed to replace the cumbersome method of firebrick construction, but preserve the quality appearance of masonry. Precast panels eliminate the failure costs of firebrick, due to expansion and contraction, while offering the home owner a beautifully clean fireplace interior.

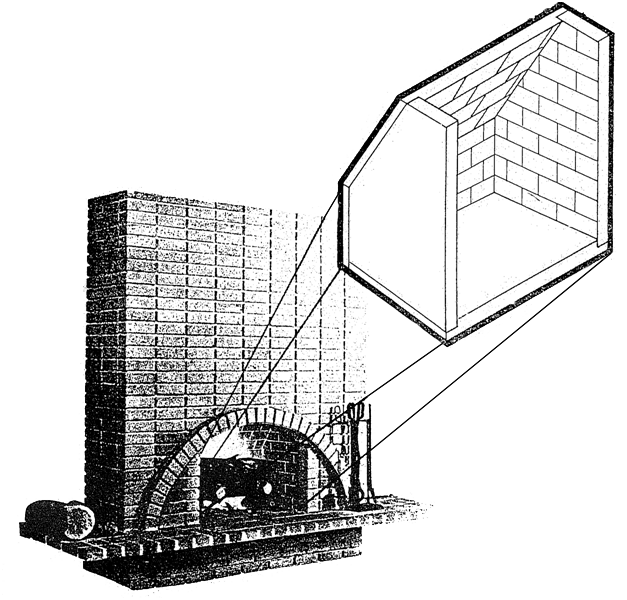

Each of the five monolithic panels which comprise a Standard firebox is texture-molded and colored (tan) to resemble a brick interior, and because of their rabbeted joints and even form, these panels fit snugly together for perfect construction without cutting. The refractory property of the Precast fireplace provides a high degree of heat reflectance, and the uncommon resistance to thermal conductance allows an insulation value equivalent to some six inches of ordinary firebrick. For the first time, a home builder can construct a fireplace without time-consuming saws, and in any weather by simply providing his brick mason with Standard Precast fireboxes.

These five sturdy monolithic slabs of insulating refractory materials with rabbeted joints make up the preferred firebox for fireplace construction.

Set the firebox by leveling the floor in desired position. The back and one side are set next, located by the groove in the floor. Slabs are temporarily held in place by tie wires provided. Next the other side can now be set, being sure all points are pulled up. Back the firebox up tight as you would firebrick…to about 16 inches high, holding these four slabs permanently. Bear in mind that building codes state eight inches of masonry must be maintained from the rear of the firebox wall to outside of stack. Now the lid slab in position and finish backing-up the firebox. With damper and smoke chamber, your modern firebox is now complete.

NOTE TO BUILDERS

The building of a fireplace that performs properly is not luck, but a filling of 4 basic requirements.

- Proper combustion of fuel

- Delivery of smoke up the chimney

- Maximum radiation of heat

- Simplicity and fire safeness

All of these are fulfilled to a better degree through the use of refractory linings of the combustion chamber or firebox. Such liners offer better looking, longer-lasting, better operating fireplaces.

TO FINISHED FIREPLACE 20 Ft. Height* - 10%

OPENING 25 Ft. Height* - 8%*Height from Hearth to Top of Chimney

Specifications

Always have 1" heat barrier around box.

Never Pour Solid.

Build Walls ¼-1/2" higher than box.

Do not set damper on box.

Damper sets on angle irons.

Angle irons sit on brick.

Temperature at hottest point in average fireplace: approx. 1100°F max.

Recommended service temperature limit: 2200°F

Melting Point: 3000°F

Safety factor allowance: 800°F

Compressive strength:

cold: 3930 PSI

after 4 hrs. at 1500°F : 1810 PSI

Insulative - Refractory value = 4" ordinary firebrick

Available firebox dimensions in inches:

No. A B C D E F G H I FLUE 18 18 14 14 18 20 8 14 6 16 8.5x13 24 24 16 17 22 24 8 14 6 16 8.5x13 32 32 17 25 30 24 8 14 6 16 8.5x13 36 36 21 28 34 26 8 14 6 16 13x13 42 42 20 32 34 28 8 14 8 16 13x17 48 48 22 41 38 32 8 14 12 16 17x17 Consult manufacturer for other requested sizes upon special order.

Available in 2 floor types for all dimensions:

Solid

Ash DumpPrecast Refractory Fireboxes comply with the Uniform Building Code and are FHA accepted. Manufactured according to the requirements of the Uniform Building Code: see Research Recommendation No 2990 of the International Conference of Building Officials.